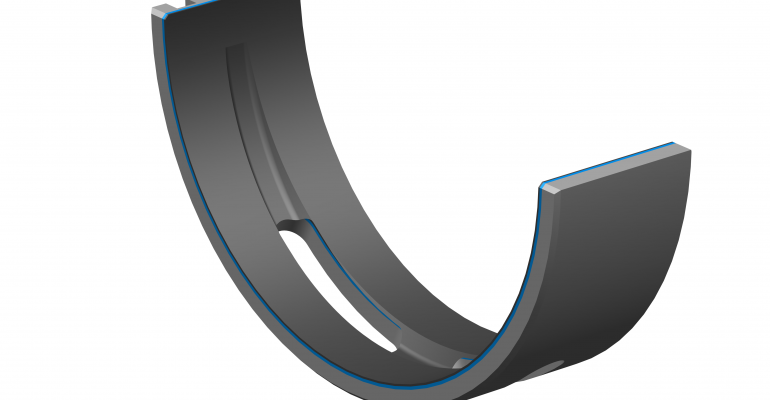

Rheinmetall Automotive launches a new generation of main and connecting-rod bearings engineered to withstand hybrid vehicles’ high ignition pressures and increased use of low-viscosity oils.

The first generation of hybrid engines used moderate start/stop technology and increased ignition pressure. The next stage, either mild or plug-in hybrids, raises the number of start/stops during a vehicle's lifespan from 400,000 to over 1 million. Combined with belt-driven 48-volt starter/generators, this has considerably increased belt forces on the crankshaft bearings and led to a substantial rise in mixed friction.

Rheinmetall’s KS Gleitlager subsidiary introduced two highly wear-resistant materials, KS R53L1 polymer for crankshaft bearings and Polymer KS R55L1 for gasoline-hybrid connecting-rod bearings at the recent Frankfurt auto show.

KS R53L1 offers excellent wear resistance with no loss in other important properties such as robustness and coefficient of friction even under the most adverse mixed-friction conditions. The R53 material acts as substrate beneath the new L1 polymer layer system, providing added robustness thanks to its special dirt tolerance, Rheinmetall says in a news release.

KS R55L1, for hybrid gasoline connecting-rod bearings, is a combination of the L1 polymer layer system with the more resilient R55 two-layer substrate material. In medium- to high-duty gasoline engines, the new KS R55L1 provides the wear resistance required on full hybrids and low oil viscosity applications, as well as high dirt tolerance.

With the use of low-viscosity oils and the surge in start/stops, both crankshaft and connecting-rod bearings operate more and more in a condition of mixed friction. Thanks to solid molybdenum disulfide and graphite lubricants already featured on Gleitlager’s first generation of polymer bearings, the new KS R53L1 and KS R55L1 polymer bearings demonstrate a low coefficient of friction throughout the entire mixed-friction range. This helps reduce crankshaft friction losses and, in turn, lowers fuel consumption and emissions, Rheinmetall says.