The battery industry needs to invest at least $514 billion across the supply chain to meet expected 2030 demand and $920 billion by 2035, according to market analysts Benchmark Mineral Intelligence.

The London-based researcher/price reporting agency predicts demand for lithium-ion batteries will grow to 3.7 TWh by the end of the decade, up from 1 TWh this year, due mainly to growth in electric-vehicle sales.

Of the 2030 demand total, Benchmark estimates China will account for 40%; Asia excluding China (namely Japan and South Korea), 10%; Europe, nearly 30%; and North America, 20%.

Of the 2030 investment total, $220 billion (43%) will be for critical raw materials, $201 billion (39%) for battery production, both new plants and expansions, and $93 billion for battery materials, including anode, cathode, electrolyte and separator production (see list below).

Benchmark warns that without investment in midstream processes, the gigafactories coming onstream “won’t be able to operate at full capacity.”

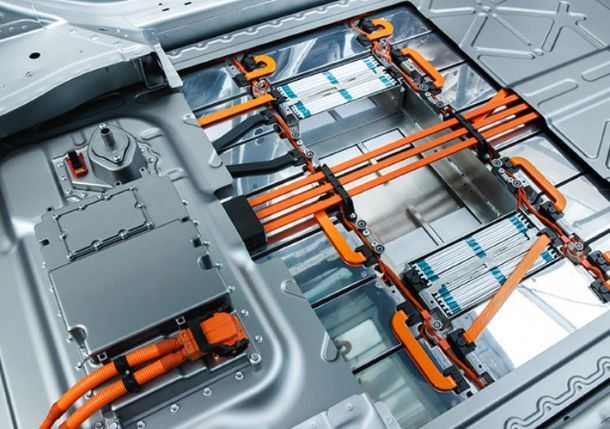

Lithium-ion battery in Jaguar i-Pace.

The firm adds that lithium production will need to grow to 2.8 million metric tons, up from 1 million t in 2023. That will require a $51 billion investment.

“More than any other part of the supply chain, lithium will be the bottleneck for the growth of the battery industry,” according to the analysis.

Lithium will be followed by nickel. Benchmark estimates there will be a gap of nearly 2 million tons between production today and projected 2030 demand. To meet 2030 demand, the industry will need to invest $66 billion, it says.

The supply shortfall in natural and synthetic graphite will be 3.6 million tons, requiring a $4.5 billion investment.

Factions in the auto industry are challenging the rationale of the EPA’s proposed rules to mitigate greenhouse gas emissions by increasing the sales of EVs and retiring more gasoline-powered internal-combustion-engine (ICE) vehicles. John Bozzella, CEO of industry group Alliance for Automotive Innovation, recently wrote that reaching a target proposed by the EPA of EVs comprising 67% of auto industry sales by 2032 is unrealistic because of supply chain issues limiting the availability of lithium.

"EPA should ease up and reassess this rule before it helps cement China’s place in the U.S. auto market," Bozzella says. He predicts that if the EPA regulations are too tough, China will gain "a stronger foothold in America’s electric vehicle battery supply chain and eventually our automotive market."

Lithium mine in Silver Peak in west-central Nevada.

Meanwhile, Benchmark estimates the industry will have to invest $40 billion for cathode and $15 billion for anode production to meet 2030 demand.

The research firm notes the bulk of cathode investment will focus on LFP (lithium iron phosphate) and NCM811 (nickel-cobalt-manganese) chemistries.

Benchmark, backing up the concerns voiced by Bozzella, warns that China currently dominates every segment of the battery supply chain. Moreover, China “has built up substantial expertise in building production facilities at a relatively low cost,” it reports.

As an example: North Carolina-based Albemarle, which is constructing 50,000-ton lithium conversion plants in Meishan, China, and Chester County, SC. Albemarle’s China facility, according to the supplier, will cost an estimated $500 million to construct. Its South Carolina plant: $1.3 billion.

Benchmark further notes that a gigafactory can be constructed in two to five years and a refinery in two years. But it takes between five and 25 years to develop a mine. Because of that, according to the analysis, it is imperative that investments in mining be made now. Otherwise gigafactories “will stand idle with production constrained by limited feedstock.”

Investments needed by 2030, broken down by upstream and downstream processes:

Upstream

Raw materials: $220 billion

- Nickel: $66 billion

- Lithium: $51 billion

- Cobalt: $9 billion

- Natural graphite: $3 billion

- Synthetic graphite: $1.5 billion

- Manganese: $0.5 billion

- Recycling: $24 billion

- Other: $65 billion

Downstream

Battery Materials: $93 billion

- Cathode: $40 billion

- Anode: $15 billion

- Electrolyte/Separator: $38 billion

Batteries: $201 billion

- New capacity: $112 billion

- Expansions: $89 billion

Source: Benchmark