The Ward’s 10 Best engines competition has recognized outstanding powertrain development for 17 years. In this installment of the 2011 Behind the 10 Best Engines series, WardsAuto looks at the development of GM’s innovative Voltec propulsion system.

In a trend driven by changing technology, WardsAuto editors increasingly are honoring entire vehicle propulsion systems as an “engine.”

It first happened way back in 2001, when the then-new Toyota Prius was honored for its game-changing hybrid-electric -vehicle powertrain.

Other HEVs have been named to the list since. This year, Nissan’s all-electric Leaf made the cut, as did General Motors’ Chevy Volt extended-range EV.

As we said about the Leaf: “If it puts power to the wheels of a new-for-’11 passenger vehicle, it’s eligible for a Ward’s 10 Best Engines award.”

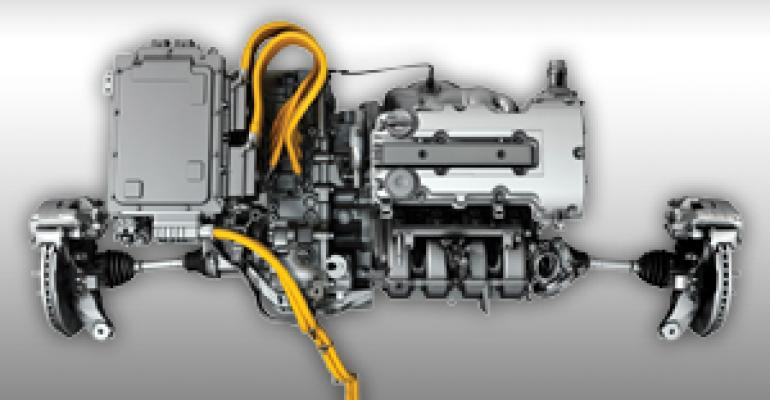

Unlike the Leaf, the Volt actually has an engine, a fine but unremarkable 1.4L naturally aspirated, port-injected, dual-VVT 84-hp DOHC 16-valve 4-cyl. What is remarkable is the way it is tuned to operate so seamlessly and efficiently with the rest of the propulsion system.

Flash back to a December 2006 pre-Detroit auto show GM press conference. Invited auto writers did not know what to expect and were surprised to find then-GM Product Development Vice Chairman Bob Lutz opening the presentation, a sure sign of its importance.

It turned out Lutz was revealing the 2007 Chevy Volt concept car and its revolutionary “E-Flex” (now “Voltec”) propulsion system, which would be unveiled a month later at the January show.

Unlike any other EV or HEV journalists had seen, the Volt’s electric drive motor was powered by a battery until its power was depleted, then by electricity from a generator driven by a small gasoline engine.

It was designed to be a non-fuel-burning, tailpipe-emissions-free EV for typical commutes. It also was a fuel-efficient compact on longer drives, running on inexpensive grid power for the first 40 miles (64 km) or so, then as far as desired on internal combustion engine-generated electricity.

It was a bold strategy to blend EV and ICE propulsion in a way that eliminates driver “range anxiety” which plagues EVs powered only by batteries.

But the skepticism of most leaving the press conference was justified: How well would this system work? Would GM have the commitment and resources to get it done, and do it right? Could the car be sold profitably at an affordable price?

Also, who knew then that the Volt program would have to survive a 2008 economic meltdown and the GM bankruptcy that followed? Yet it did, quite nicely, thank you.

After naming the Volt propulsion system one of Ward’s 10 Best Engines for 2011, WardsAuto editor Tom Murphy declared it “a car that revolutionizes mobility.”

The January 2011 10 Best Engines summary proclaimed it, “a magnificent achievement that marries the best attributes of all-electric vehicles with those of fun-to-drive, fuel-efficient gasoline cars.”

It also added: “Despite the complexity and the seamless switching between driving modes, it’s all utterly transparent to the driver.”

The Volt’s 1.4L is a member of GM’s smallest global family of Ecotec engines, the substantially improved third generation, which arrived stateside (in turbocharged form) in the ’11 Chevy Cruze.

Probably its most significant upgrade is the addition of dual independent cam phasing (VVT), says 1.4L Ecotec Assistant Chief Engineer Mike Katerberg. Current versions include a 1.0L I-3, 1.2L I-4 and both the turbo and naturally aspirated 1.4L 4-cyl. engines.

Key design elements are a 40-mile (64 km) EV range and the capability to extend that range with an ICE engine that acts as a generator, says Volt Propulsion System Chief Engineer Pamela Fletcher. Another major goal is to deliver a driving experience similar to a conventional car.

This naturally aspirated 1.4L was chosen to deliver the most output from the smallest physical package. It already was fully developed and its reliability and durability established.

Could it have been smaller in displacement and turbocharged? In the Volt application, such an engine would be less efficient, Fletcher says.

| GM | 1.4L DOHC I-4/111 KW DRIVE MOTOR |

| Battery | 16 KWH lithium-ion |

| Drive Motor | 111 kW |

| Generator Motor | 54 kW |

| Max Power | 149 hp |

| Torque | 273 lb.-ft (3638 Nm) |

| Bore x stroke (mm) | 77 x 85.8 |

| Engine Site | Flint, MI |

| Electric motor site | Bay City, MI |

| Battery assembly | Brownstown, MI |

| Application Tested | ’11 Chevy Volt |

| EPA EV mode | 93 mpg equivalent (2.5 L/100 km) |

| EPA gas mode | 37 mpg (6.4 L/100 km) |

| EPA combined | 60 mpg (3.9 L/100 km) |

“The reality is there is a requirement for how much output and generation capability you need for the most extreme conditions; for example a very long, steep grade at higher altitudes,” Fletcher says. “If you look at where the engine wants to operate in this electrified configuration, around 2,300-2,400 rpm, the turbo is not as efficient as the naturally aspirated engine.”

One reason a small-displacement turbo engine is fuel efficient in a conventional car is that it can run unthrottled 80% to 90% of the time, Katerberg says. “But when you're into the boost, you’re better off with a comparably powered naturally aspirated engine.”

“With the Volt, we’re almost always running at wide-open throttle at maximum power, because that’s where a naturally-aspirated engine is most efficient.”

In fact, the only time it is not at wide-open throttle is when noise, vibration and harshness would be a problem. “If the engine is on when you’re at or near zero vehicle speed, for example, you don’t want it running wide open,” he says.

Replacing the gas engine with a small turbodiesel might sound like an even more efficient route, but engineers say a diesel would have been heavier and more expensive.

Plus, it would have required the complex and costly exhaust aftertreatment systems necessary for diesels to meet U.S. emissions requirements. There were many other hurdles as well.

“The whole mindset and attitude of the Volt team had to be different because of the challenge we were given and the time we had to accomplish it,” Fletcher says.

“Every day, we had a list of interesting new opportunities. Some were things acting differently than we expected. But some were additional capabilities that we hadn’t thought about. If we had looked at things as problems, we would have been overwhelmed.

“With this system, you can have additional features and enhancements that you can’t have without electrification,” she says.

For example, unlike most cars, the Volt is unaffected by altitude when running in electric mode. And even when it gets into range-extending mode on a long grade, it has the ability to use its generating system to make its performance near what it would be on less aggressive terrain, Fletcher says.

But to be certain the powertrain has good noise, vibration and harshness characteristics, the vehicle requires a certain amount of power, Katerberg says. “You have different engine points where you can run to deliver that power, and the control system picks where it runs to optimize efficiency.

But there are conditions that would be disconcerting to the customer, like running wide-open throttle when the car is stopped. You have to manage that appropriately while taking into account the amount of power the system needs,” he says.

The team also took special care with the battery to confidently offer an 8-year, 100,000-mile (161,000 km) warranty.

“A lot of people are interested and excited about the technology, but can get a little squeamish if they’re worried about the number of miles and years that everything will work as intended,” Fletcher says. “We also wanted to provide consistent performance through the life of the car, so a lot of precautions were taken to be able to do that.”

Are there opportunities for future improvement?

“The data is saying that most customers are driving electrically most of the time,” she says. That tells us that we got the right recipe for this market, but how do we keep that recipe and do it for lower cost? We need the parts to be smaller and less expensive with potentially higher performance.”

“We could have made it a 100-mile (161-km) EV-range car by putting in more battery and sacrificing some interior space. But why would you pay for that? Why would you ask the customer to pay for even 50 miles (80.5 km) vs. 40 (64 km) when our data shows overwhelmingly that the EV range we have now meets most people's needs.”

But Fletcher quickly adds that does not imply the next Volt will be the same.

“When we do the next-generation Volt, everything is fair game,” Fletcher says. “We’re going to look at every system and make the best choices we can.”

Direct injection could provide meaningful improvement, but at added cost. What about the Volt’s need for premium fuel?

“The way we run the engine allows it to capitalize more on the benefits of premium than a conventional vehicle would because we’re always operating near those knock-limited points,” she says.

“When you do the value equation for this generation, it makes sense, and we'll go through that value equation with every car we do.”

A lot of assumptions were made about how owners would use the Volt and what they would and wouldn’t like about it. GM’s early customer research is validating the very important belief that most owners will drive it less than 40 miles a day.

“More than two-thirds of our customers are driving all electric all the time,” Fletcher says. “So this idea of optimizing around the electric mode with the range extension as a back-up plan is really coming true.”