Five TVS Programs Boosting Eaton’s Supercharger ProspectsFive TVS Programs Boosting Eaton’s Supercharger Prospects

New business has Eaton expanding its supercharger plant in Tczew, Poland, with potential expansions coming in the U.S. and China. Eaton also is moving forward with research into diesel superchargers.

SOUTHFIELD, MI – Thanks to this year's launch of the innovative new Twin Vortices Series supercharger, Eaton Corp. plans to boost its annual production of superchargers globally by 80% over the next two years.

The aggressive ramp-up includes seven OEM programs for multiple customers, and five of those contracts are dedicated to TVS production, Joao Faria, president of Eaton's Powertrain and Specialty Controls Business, tells Ward's in an interview here.

The remaining two programs call for Eaton's fifth-generation superchargers, which have been on the market since 2002 and constitute most of Eaton's volume.

Eaton will produce about 400,000 superchargers this year. The additional volume from the new contracts is forcing expansion within the next year of the supplier's plant in Tczew, Poland, which opened in 2005, and Eaton may have to add capacity at its sole North American supercharger plant, in Athens, GA, Faria says.

“Obviously, this volume would require additional capacity, no doubt,” he says.

In Asia, where Eaton has landed its first supercharger contract, the supplier is considering tooling up a facility in China, Faria says. Sales volumes will dictate whether further expansion is necessary.

Faria says no additional staffing will be needed to meet 2009 production needs. “As for 2010 and 2011,” he says, “we still don't have the picture yet.”

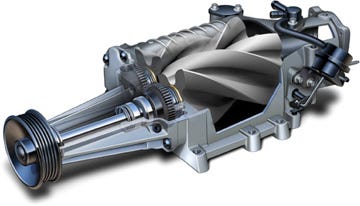

Eaton's TVS Roots-type supercharger with 4-lobe rotors enables greater volumetric capacity at higher engine speeds.

Eaton is finishing one of its best years ever in the supercharger market, driven by high-profile TVS launches for the '09 Chevrolet Corvette ZR1 and Cadillac CTS-V, the first North American applications for Eaton's sixth-generation blower. For each vehicle, the unit integrates with an intercooler.

With headquarters in Cleveland, Eaton has produced some 4 million Roots-type superchargers since 1989, with the Ford Supercoupe serving as the first application.

Three years later, the company began supplying General Motors Corp. with superchargers to be mated with the long-standing 3800 V-6. That relationship lasted more than a decade.

Until the ZR1 and CTS-V programs, Eaton's only other supercharged GM engine was the similarly low-volume 4.4L Northstar V-8 for the Cadillac XLR-V and STS-V.

Eaton began producing its fifth-generation supercharger in 2002 (with Mercedes-Benz as the first customer), and that design consisted of two helical-shaped rotors, each with three lobes that twist against each other to force a large volume of air into the combustion chamber.

Like the fifth-generation unit, the new TVS incorporates two helical-shaped rotors machined from aluminum extrusions. But each TVS rotor has four lobes that mesh together at steeper angles, allowing 160 degrees of twist vs. 60 degrees with the previous unit.

With the fourth lobe and added twist, as well as redesigned air inlet and outlet ports, the new TVS creates a smoother, more efficient flow of air into the engine, says Grant Terry, Eaton's

product strategy manager-Supercharger & Cylinder Head Systems Division.

More air into the combustion chamber means more power, which is music to the ears of muscle-car aficionados. The TVS boosts GM's 6.2L V-8 to a trooper-baiting 638 hp in the Corvette ZR1 and 556 hp in the Cadillac CTS-V.

TVS supercharger boosts GM's 6.2L V-8 to trooper-baiting 638 hp in Corvette ZR1.

Despite the stampede of horses, the new design makes for a much quieter supercharger, addressing one of the biggest complaints about high-powered blowers. And the new unit isn't any larger than the old one, which will reduce packaging concerns underhood.

The new supercharger operates at a lower air pressure and can spin at speeds up to 18,000 rpm, while the fifth-generation unit was limited to 14,000 rpm, Terry says.

TVS represents a natural progression for Eaton's supercharger product range, Terry says. “We went as far as we could with the 3-lobe rotor” in terms of efficiency and functionality.

Terry's key metric for supercharger functionality is thermal efficiency, which he says improves from 62% on the fifth-generation unit to 75% on TVS.

“We're now playing where turbochargers play,” in terms of thermal efficiency.

Turbochargers grossly outnumber superchargers in OEM applications, thanks to the popularity of turbodiesels and the proliferation of turbocharged direct-injection gasoline engines. However, Terry says some of the new TVS contracts managed to displace turbochargers.

While Eaton trumpets the improvements of TVS, turbochargers also are getting better, minimizing in some cases the tendency to “lag” while exhaust gases spool up the turbines to provide additional boost.

Still, Terry stands by the supercharger as the best bet for instant accelerative gratification. While the turbocharger does most of its work at middle and high engine speeds, the supercharger does its heaviest lifting at low rpm, generally at stop lights.

European auto makers are showing greater interest in supercharging. Audi AG has sourced Eaton's TVS for its all-new 3.0L TFSI V-6, which will power the S4 and A6. In the higher-volume A6, the supercharged engine is capable of 290 hp and 24 mpg (9.8 L/100 km).

Supercharging allows Audi to downsize its powertrain offerings. Rather than offering a normally aspirated 4.2L V-8 in the previous-generation S4, Audi now will offer the more compact supercharged V-6, while achieving 27% better fuel economy and a 30% reduction in carbon-dioxide emissions, without sacrificing power.

“I have seen some comparisons to the V-8, and the feedback is the performance is very, very similar to the V-8,” Terry says.

In addition, the supercharged V-6 will allow Audi to better differentiate between the S4 and the RS4, which will continue to have a higher-output V-8.

Eaton considers the Audi contract cause for celebration, given the German auto maker's long-established expertise with turbocharged engines.

“We went in and sold them the virtues of TVS and convinced them to start the program,” says Craig Sell, Eaton's engineering manager, Supercharger & Cylinder Head Systems Division. “They did a direct head-to-head comparison of the supercharged engine vs. the normally aspirated engine. The TVS supercharger provided significant advantages.”

Helping Eaton's cause with Audi was the success of parent Volkswagen Group's 1.4L TSI direct-injection gasoline engine available in the new '09 VW Golf, which is launching now in Europe and arrives in the U.S. in late 2009.

The award-winning “twincharger” 4-cyl. incorporates a half-size Eaton fifth-generation supercharger and a single-stage turbocharger to deliver the power of a larger engine (160 hp and 177 lb.-ft. [240 Nm] of torque) while achieving 39 mpg (6.0 L/100 km).

The supercharger team at Eaton continues to seek new markets and innovations for the device that dates to 1860 and gained fame on drag strips in the 1950s.

Faria refers to the company's research in “dual-drive” superchargers that improve fuel economy and performance, while reducing cost and complexity. A customer is evaluating the technology but has not yet signed a contract, he says.

Eaton also is looking seriously at supercharged diesel engines, which is bound to spark a pitched battle with turbocharger suppliers such as BorgWarner Inc. and Honeywell International Inc. (maker of Garrett turbochargers).

“We are working with various customers,” Faria says. “We have a lot of interest from Asian OEMs, some in Japan, to test the diesel. We need a bit more time before we finalize development of the diesel supercharger, but the first data has shown us good results on emissions.”

And as diesel engines become more expensive to meet impending environmental codes, Terry says a supercharged diesel might allow for less frequent regeneration of the particulate filter, which would save fuel and extend the life of the filter. Terry says this approach also downsizes the filter, which would mean fewer precious metals and reduced costs.

“I think you're going to see more superchargers going into more popular cars – higher-volume cars – than ever,” Faria says.

About the Author

You May Also Like