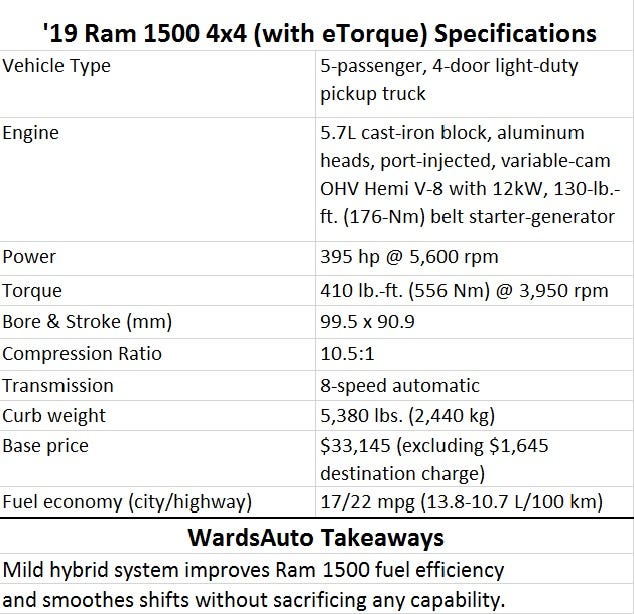

2019 Ram 1500 eTorque: No Pain, Ram Gains2019 Ram 1500 eTorque: No Pain, Ram Gains

FCA is catching up on electrification, following up on the mild-hybrid Wrangler with an eTorque-enabled Ram 1500 pickup.

LEXINGTON, KY – Seamless. Nearly imperceptible. Almost invisible.

Those are a few descriptors for the electrified powertrain in the ’19 Ram 1500 pickup, featuring FCA’s new eTorque 48V mild-hybrid system.

Available as standard equipment on the 3.6L Pentastar V-6 and as a $1,450 option on the 5.7L Hemi V-8, the belt-driven motor-generator effectively improves fuel efficiency without any noticeable change in the operation of either powertrain, except for the addition of a relatively low-vibration stop/start function.

In our test drives in urban driving as well as on winding routes through Kentucky bourbon and horse country, the two powertrains performed so smoothly as to be nearly imperceptible to the driver.

The only clear difference is the fuel-saving stop/start operation, which smoothly fires the engine in either application; FCA says restart time is half that of a normal starter, which is still onboard to provide initial key-turn ignition. The Hemi saves 1.7 oz. (50 ml) of fuel every 90 seconds during a shutdown, Ram 1500 chief engineer Mike Raymond says.

eTorque motor-generator sits high on block on 5.7L Hemi V-8.

eTorque motor-generator sits high on block on 5.7L Hemi V-8.

In city driving, eTorque provides a 2-mpg (0.87 km/L) improvement in fuel economy in the 5.7L Hemi and a 3-mpg (1.3 km/L) gain for the V-6, according to the EPA. In 2WD trucks, the e-Torque-enabled V-8 is rated at 17/23 mpg (13.8-10.2 L/100 km) city/highway, while the V-6 achieves 20/25 mpg (11.7-9.4 L/100 km) city/highway. 4WD trucks are rated at 17/22 mpg (13.8-10.7 L/100 km) for the eTorque Hemi and 19/24 mpg (12.4-9.8 L/100 km) for the eTorque Pentastar.

Unlike some electrified powertrains designed to add power or torque in addition to the internal-combustion engine’s output, eTorque instead saves fuel by replacing power the ICE would otherwise have to generate.

As a result, total output remains the same for both the 395-hp, 410-lb.-ft. (556-Nm) V-8 and the 305-hp, 269-lb.ft. (365-Nm) V-6, with eTorque blending 130 lb.-ft (176 Nm) of torque with the V-8 and 90 lb.-ft (122 Nm) with the V-6.

During our drive of the eTorque-equipped 5.7L Ram, Brian Spohn, FCA vehicle electrification engineer, explains eTorque’s assistance is most prominent under normal acceleration from a stop as the system restarts the engine at about 400 rpm and provides its full torque up to 1,100 rpm when the ICE fully takes over.

“Keep in mind, all of what we’re talking about is happening in two blinks of the eye,” Spohn says.

After that, the electrical equipment mainly functions as a 240A generator while cruising and during deceleration and braking, and adds torque to the crankshaft to smooth shifts by the 8-speed automatic transmission.

Try as we might, we found the eTorque system’s machinations virtually undetectable, perhaps adding a touch of extra oomph from launch, but that might have just been the big Hemi talking. FCA says the standard and eTorque V-8 trucks run even in comparison testing.

The generator recharges a 12-cell, 430Wh lithium-ion nickel manganese cobalt-graphite battery pack while also sending electricity to a 3.0-kW DC-to-DC converter to provide power to the truck’s regular 12V systems. The power pack, including the converter and two cooling fans, is mounted inside the rear cab bulkhead to avoid any intrusion on cabin or cargo room.

Through careful management of the charge in the 48V and 12V batteries, the system can power accessories, including the 850-watt Hemi engine cooling fan, and recharge during the most efficient operating conditions, minimizing parasitic drag on the engine and allowing expanded operation in fuel-saving 4-cyl. mode in the Hemi.

The truck also uses the eTorque motor-generator to smooth downshifts when engine fuel is cut off during coasting.

eTorque standard on Ram 1500 Pentastar 3.6L V-6.

eTorque standard on Ram 1500 Pentastar 3.6L V-6.

The V-6 and V-8 motor-generators differ primarily due to location of the units on the respective engines, Spohn explains. On the V-8, the motor-generator is located high and up front on the engine, allowing air cooling through the big Ram grille.

The V-6 unit, however, is reverse-mounted and centered on the block in an ideal location to drive the crankshaft, but requires an independent liquid cooling system to prevent it from overrunning its optimum 185° F (85° C) operating temperature. A similar liquid-cooled motor-generator is employed on the Jeep Wrangler 2.0L turbocharged 4-cyl.

The eTorque system is on sale as an option on the Hemi V-8, but is standard on all Pentastar V-6-equipped trucks.

All this adds up to a light-duty Ram pickup that offers better fuel economy with no discernible difference in drive quality at a reasonable added cost to the customer. That’s a win-win-win for an automaker that, until the introduction of the ’18 Pacifica Hybrid plug-in minivan, was considered a laggard in developing electrified powertrains. Not anymore.

About the Author

You May Also Like